Sugar Speciality Chemicals

Evaporator fouling or scaling results from the decreasing solubility of juice impurities as the juice concentration increases. The deposits formed retard heat transfer, reducing the efficiency of the evaporator. The result is that more energy is required to concentrate the juice and / or, the time required to concentrate the juice must be extended. This slowing down of the evaporation process affects total factory operations, and reduces production efficiencies. The use of antiscalants helps to reduce evaporator cleaning frequency and substantially reduces the amount of chemical required for such cleaning.

DiThiocarbamate based broad spectrum micro-biocide that can be effective in controlling the growth of algae, bacteria and fungi. The unique composition of mill sanitation chemicals are effective against both the gram positive and gram negative bacteria, as well as active against fungi.

Quarternery ammonium-based chemical – BenzalKonium Chloride, specially developed formulation for application in sugar industry. It is very effective in controlling and preventing microbial growth in sugarcane juice.

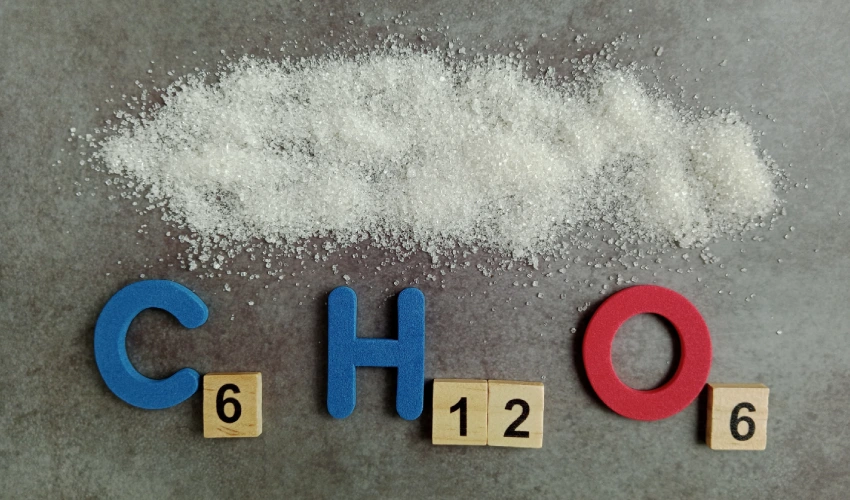

Molasses exhaustion is very important in crystallization process. The rate of growth of sugar crystals in a massecuite during boiling and crystallization process depends directly on the degree of super-saturation of the mother liquor surrounding the crystals. At high degree of super-saturation, instead of increase in the rate of crystallization, formation of ‘false grain’ occurs. This is due to concentration of non-sugars which affect the solubility of sugar and increase VISCOSITY when such massecuite is used. The final molasses purity becomes very high. It is therefore an important consideration to keep the viscosity low throughout the pan boiling.

These chemicals increase the settling rate reducing the sugar processing time immensely. They are added to a glaze to enhance the viscosity (thickness) and increase the time it takes for the glaze to settle.

The colouring matter in sugar cane juice is an undesirable impurity due to its adverse effects on crystallization process and finished sugar products. The organic non sugars are colouring matters in sugarcane and raw juice. Color Precipitant is used efficiently to thicken the sugar juice color affecting matter which will settle along with mud in the clarifier and keep sugar quality best. Due to its features such as purity, precise formulation, high effectiveness and adequate chemical properties, the offered Color Precipitant is widely demanded in the industry.

SRI DeScale is a proprietary formulation combination of speciality chemicals and necessary surface-active components. SRI DeScale can be added into scaled equipment directly without any modification of equipment in current process. Used for removing hard scales from the affected equipment.

A very effectual chemical used to improve the pH of the process water. It also efficiently decreases the bacterial action which drops down the pH. This chemical is processed using high quality chemical substances for spraying ponds. Further, this Spray Pond Water pH Booster also maintains the pH level of the water to +7 and prevents the bad odor.

Liquid oxygen scavenger is recommended for the rapid and complete removal of dissolved oxygen chemically from feed-water and boiler water. This catalyzed scavenger converts itself to sodium bisulfate and remove oxygen instantly from boiler feed water. Having precise pH value, this chemical is acknowledged for its attributes like saving power energy, minimize oxidation corrosion, removes oxygen and precise pH value.

Highly efficient Antifoam and Defoamer at low concentration levels. Foam can cause major inconvenience in industry resulting in damage to goods, overflow of vessels, and loss of valuable products and reduced plant efficiency. We supply Si based and Non-si based defoamer which can be used directly or diluted with water to get the desired concentration to kill the foam.